Goal:

Create a robot that tells time in any manner using multiple noncontinuous servos. The robot must auto set upon start up using RTC or REST API endpoint.

Final Product:

Approach:

Our approach for this project focused on utilizing the ratchet and pawl fundamental mechanism to transform the noncontinuous motion of MG90 servos to continuous hand rotation. The clock robot utilizes minute and hour hands mounted on individual ratchets that are driven by elastic band tensioned pawl arms.

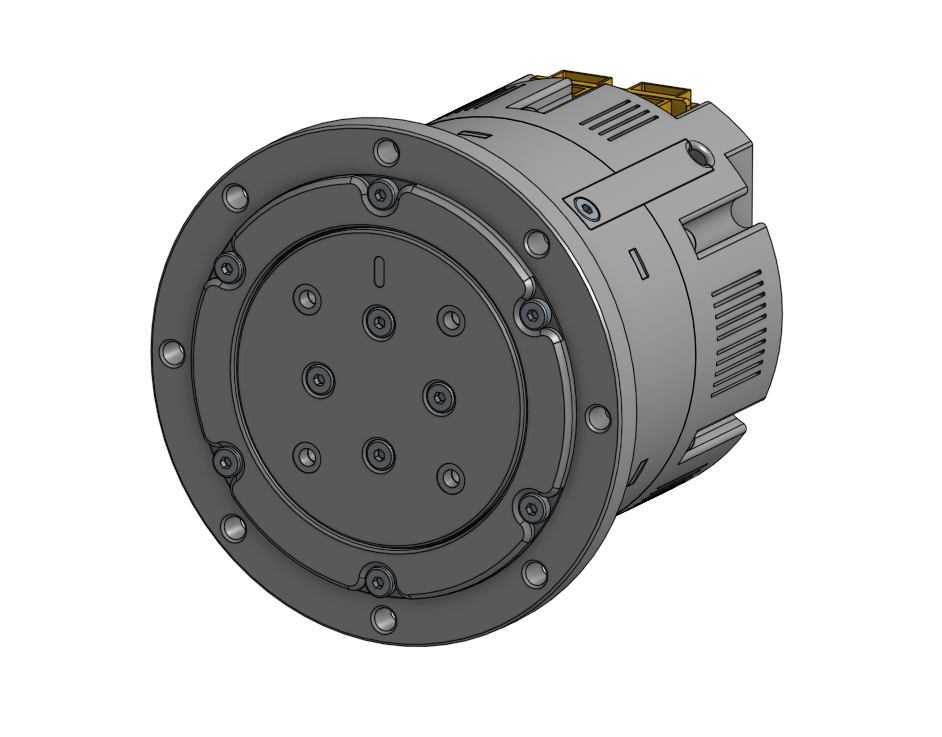

Due to COVID shutdown, all parts were modeled and sent to the campus makerspace for fabrication. The clock was modeled using Onshape and a turntable capture of the final iteration is displayed below.

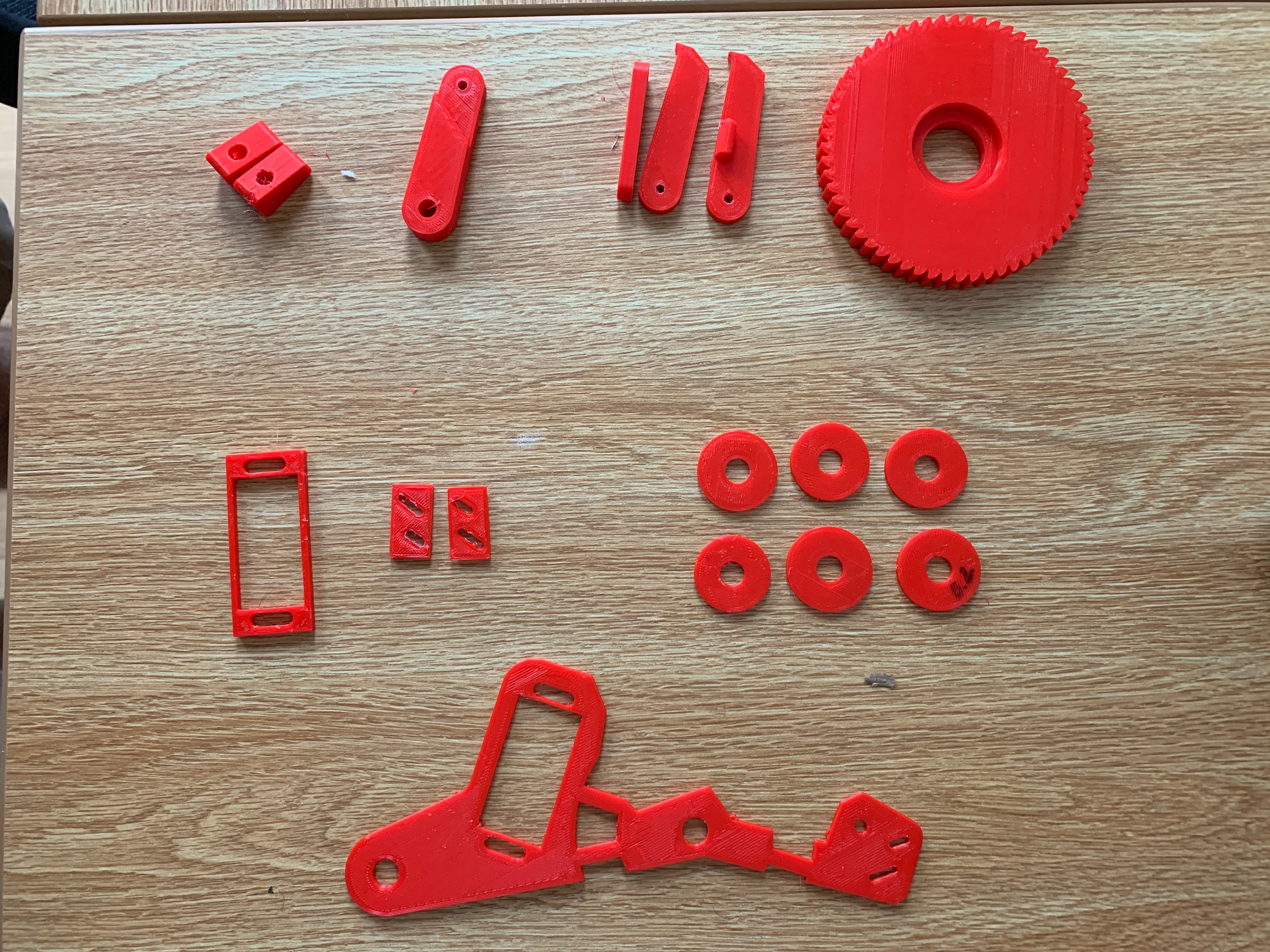

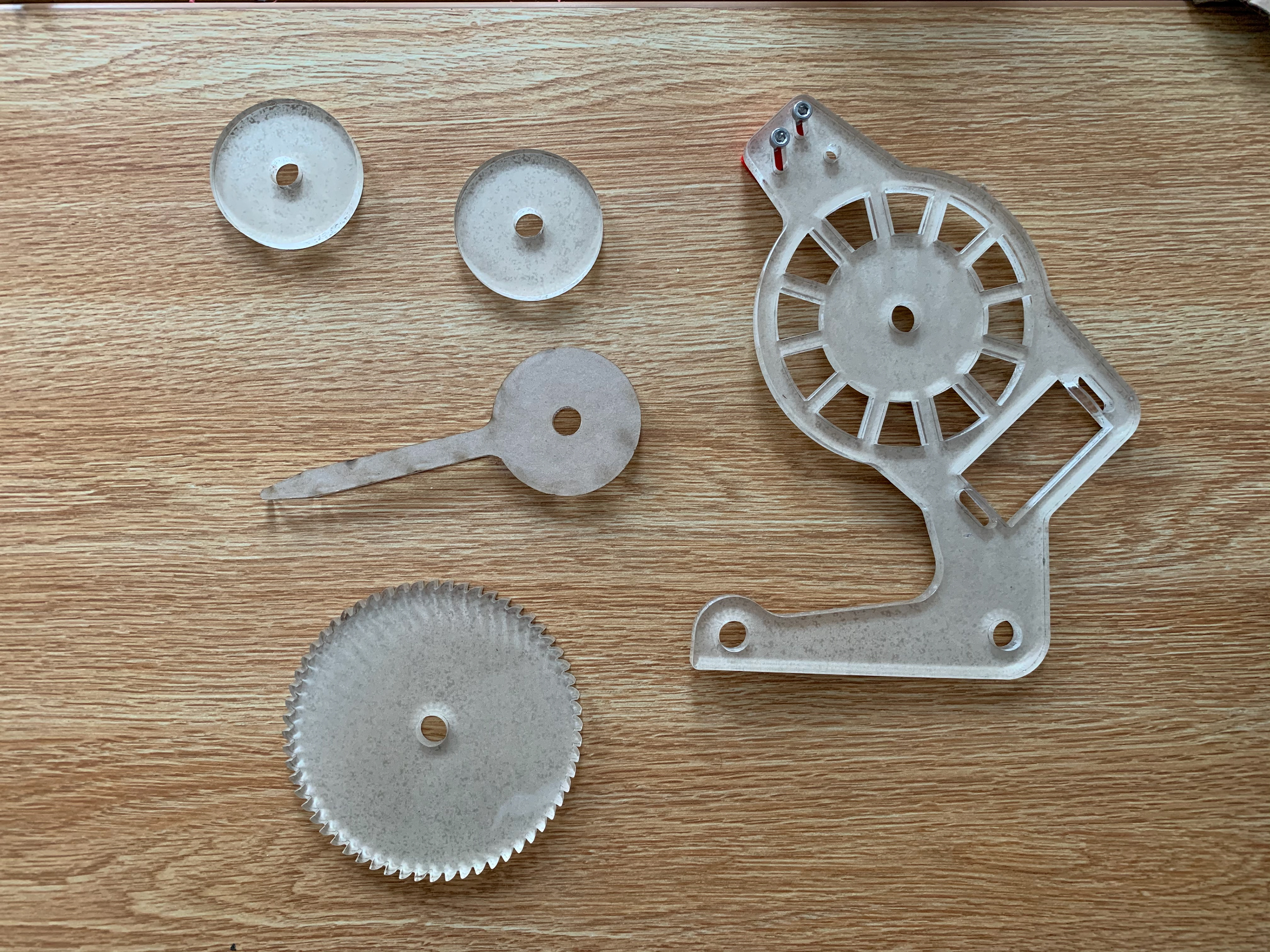

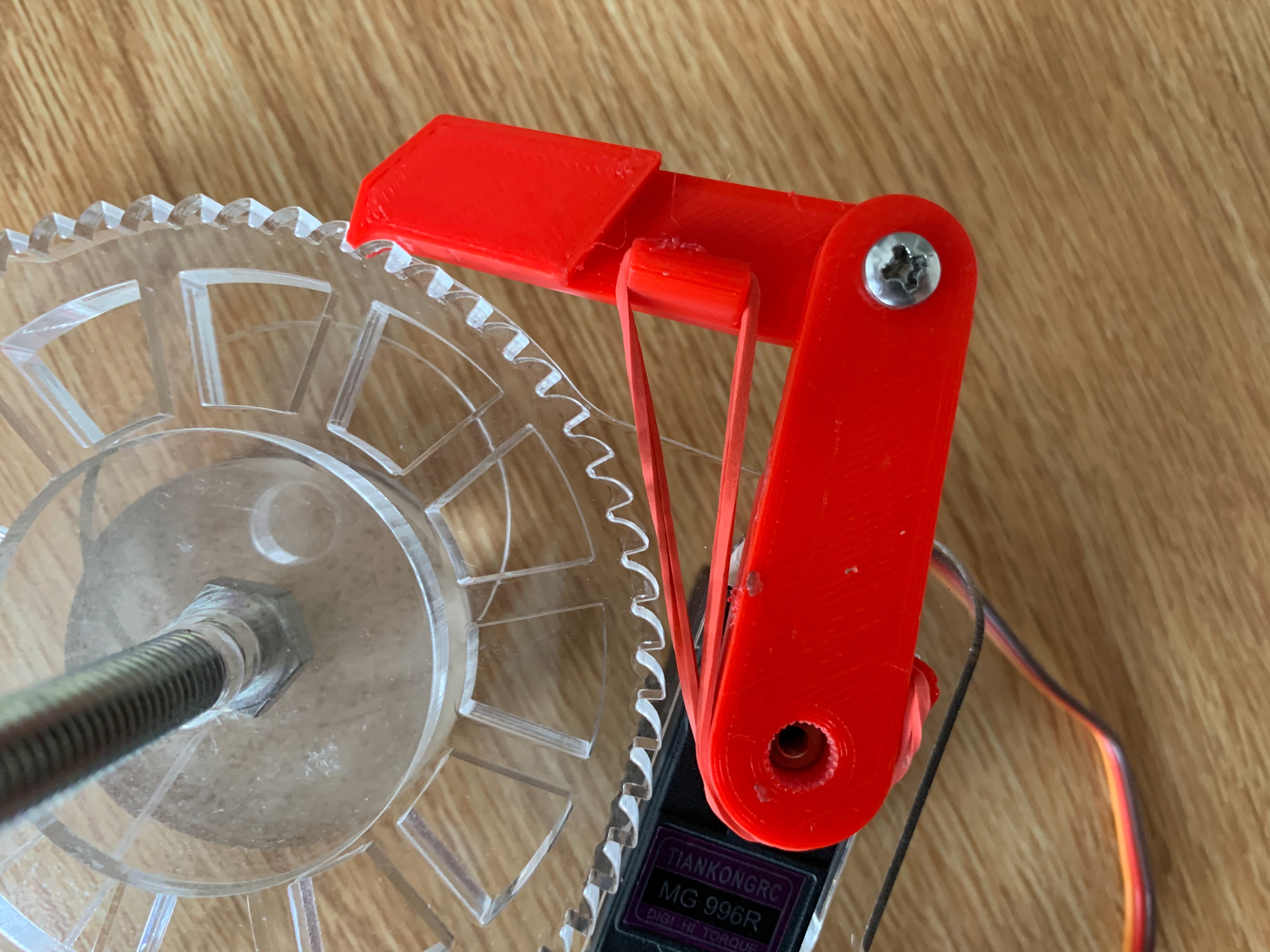

The photos below are of the parts after fabrication. 3D printing was used for tolerancing and layout test prints in order to ensure that final laser cut parts will align.

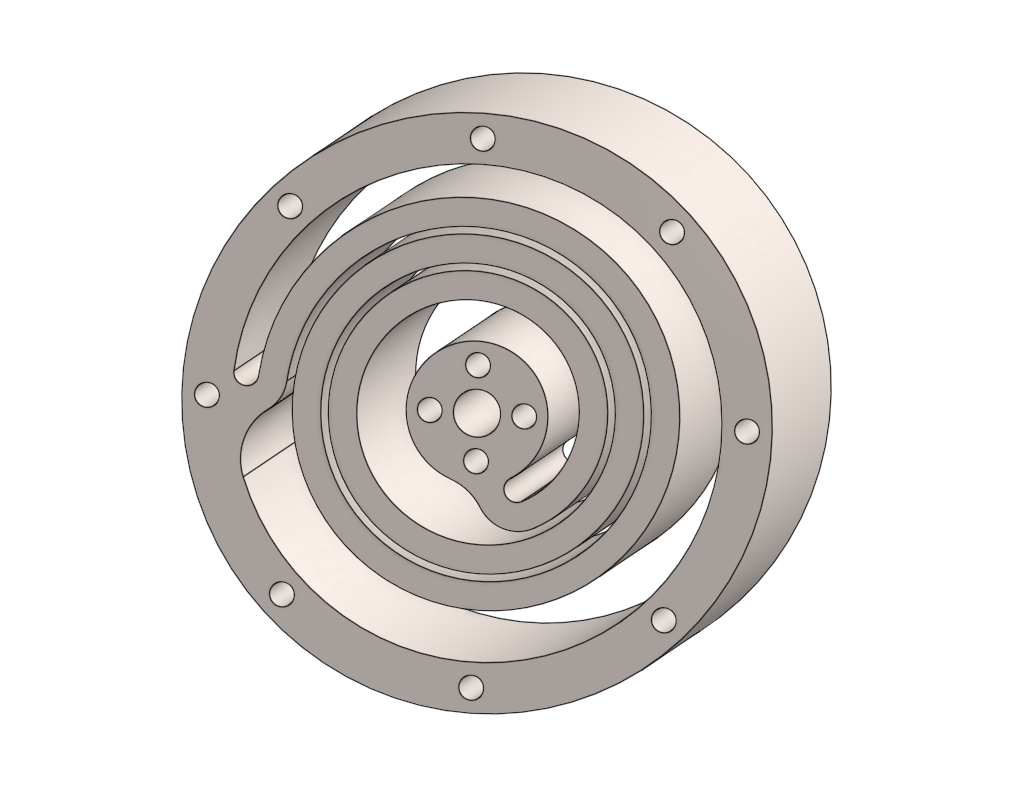

As the clock was assembled the sub systems were put together. In order to ensure proper ratchet tooth engagement the pawl was elastic band tensioned. This can be seen below along with the spring tensioning of the ratchet to prevent against spring back when transitioning between pawl strokes.

The clock design is symmetric about its central plane which can be viewed in the bottom image. The image also highlights a top down view of the complete ratchet and pawl assembly.

On the software side, the clock utilized the Python time library in order to auto set the hands to the correct position. Each ratchet has 60 teeth so once the clock is set the minute hand will move one ratchet position per minute.

Future Improvements:

Due to hardware shortages at the campus makerspace, pivots had to be constructed using M3 and M8 bolts. Planning to approach this design again in the future and replace the hardware with smooth rods to remove any possible binding introduced by the bolts.