Goal:

Redesign the PoWeR labs original torsional spring in their ankle exoskeleton by replacing original planetary gear transmission with a directly driven torsional spring.

The planar spring must have a linear spring constant to match the force of the muscles moving the ankle. Once again because the system is direct driven the range of motion of the spring must match the range of motion of the ankle. Spring must fit within the form factor of the ankle, so that the exoskeleton device doesn’t hit the ground when being worn.

With these requirements, the torsional spring must fit within these specifications:

● Linear spring constant: 1.5Nm/deg

● Maximum torsional load: 80Nm

● Maximum outer diameter of torsional spring: 100mm

Additionally, the study will consist of multiple participants hopping at their desired pace for 5 minutes, 3-4 times a week, for 15 weeks. Due to the extensive use of the spring, we aimed for it to have an infinite life.

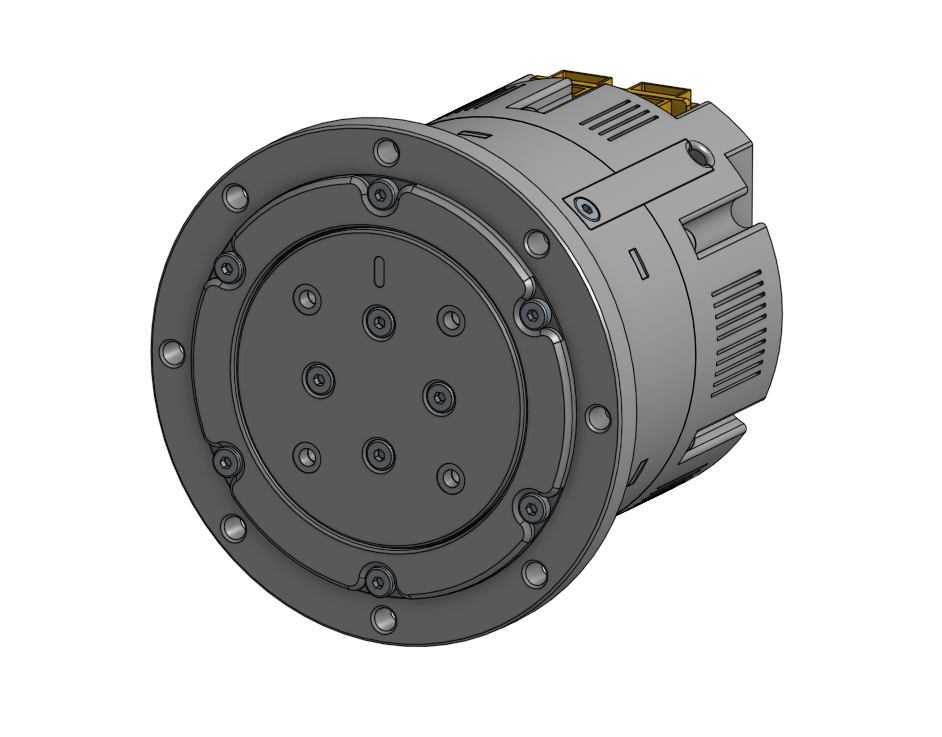

Final Product:

Approach:

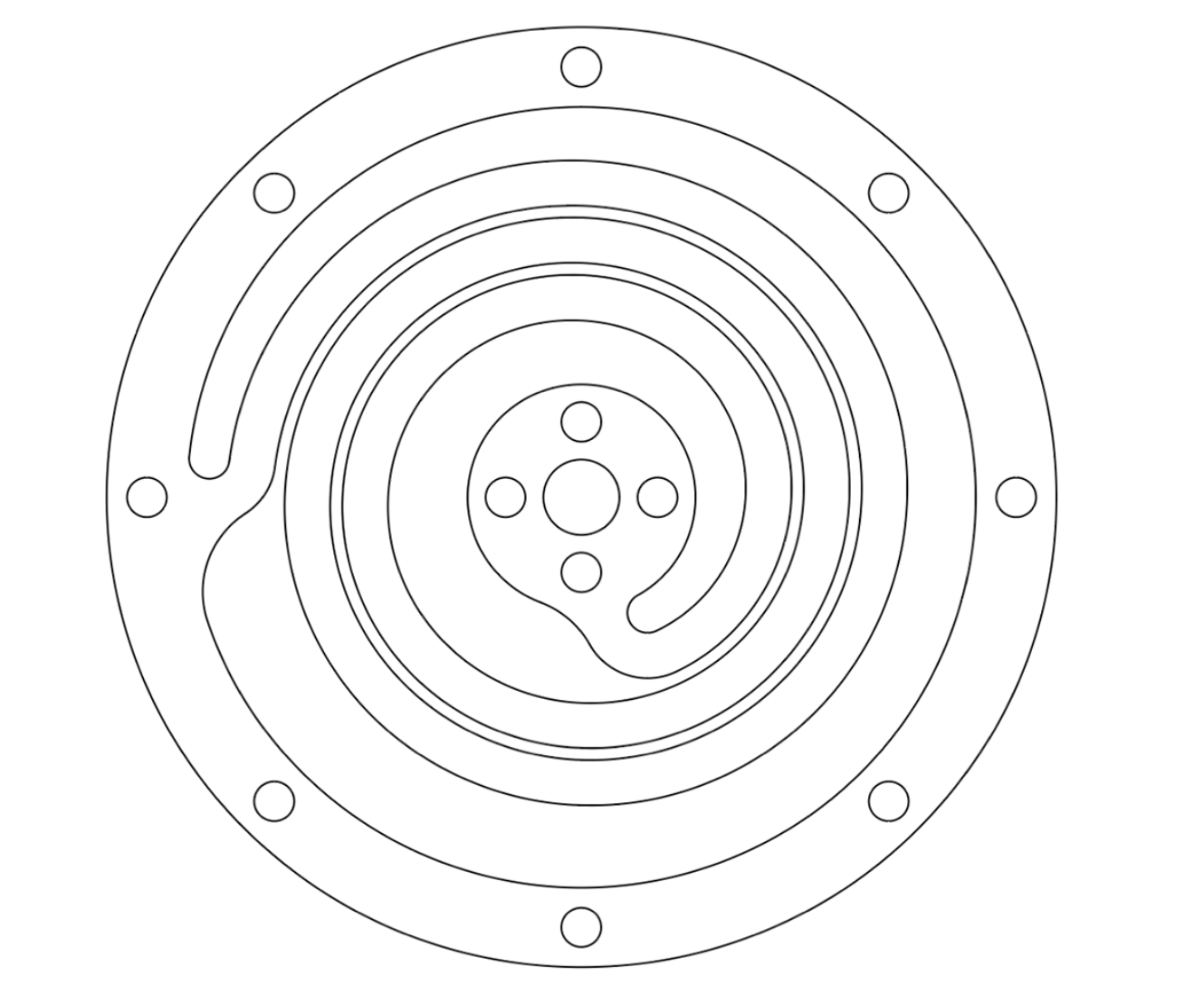

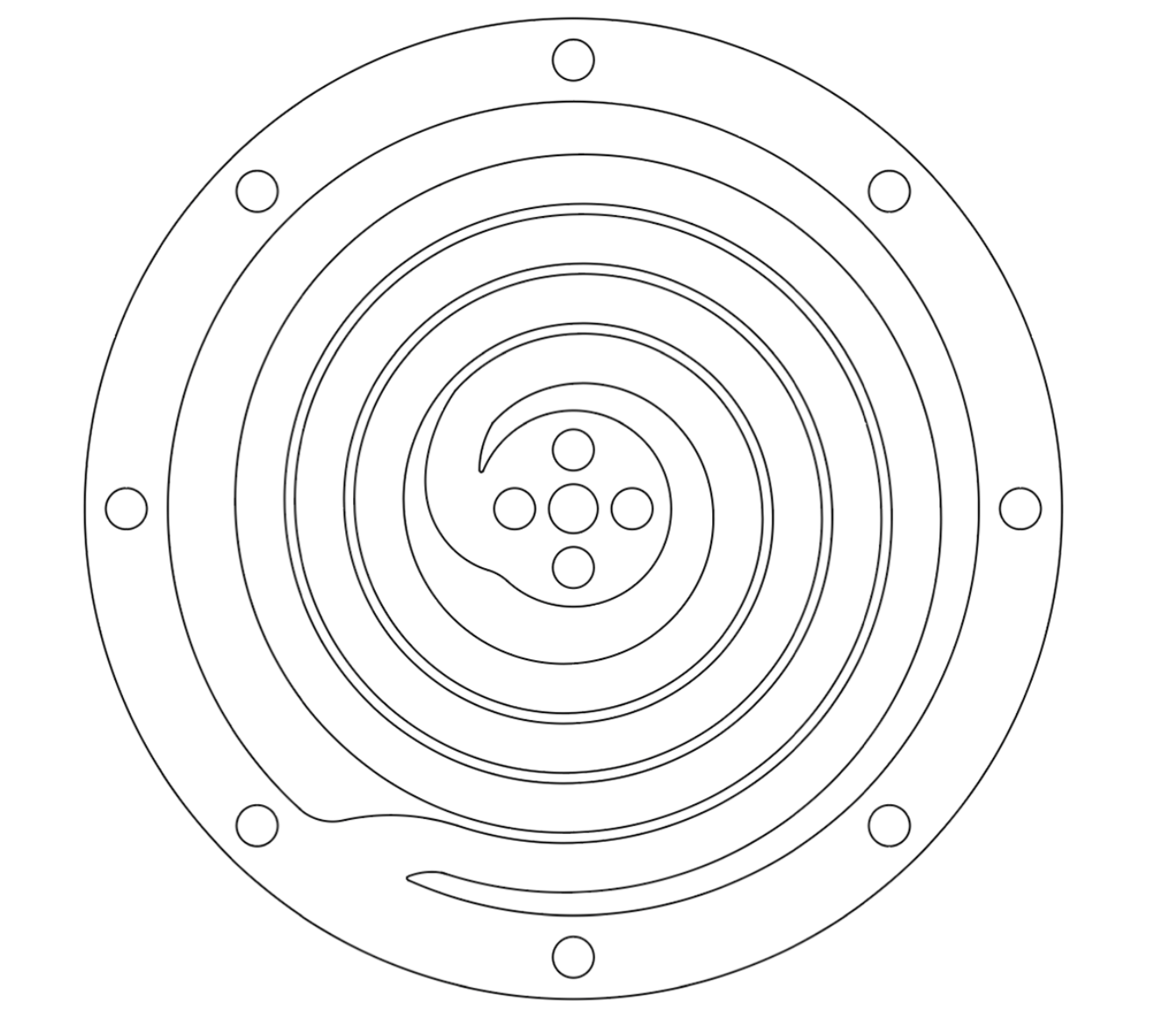

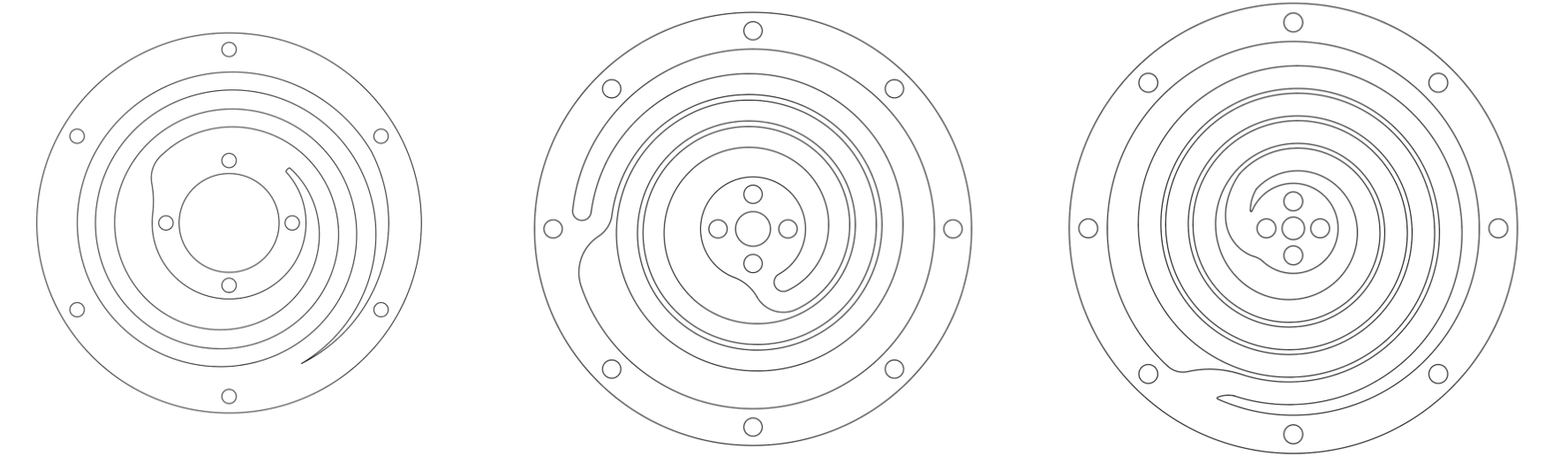

In order to achieve these design constraints we worked through various spring iterations. The first row are iterations off of the patented spline design using additional splines for increased torsional stiffness. These iterations were not able to reach the desired safety factor, load, spring constant, or range of motion without collision.

The row above is based off a beam in bending, the spiral nature leads to uniform stress concentrations across the spring. Collisions appeared in this iteration cycle as well, but we were able to find a possible solution using this approach.

Spring Testing and Simulation:

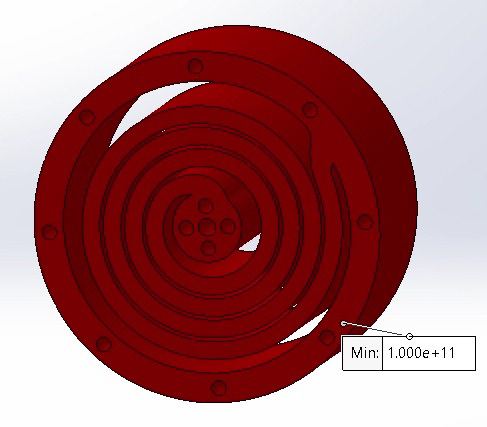

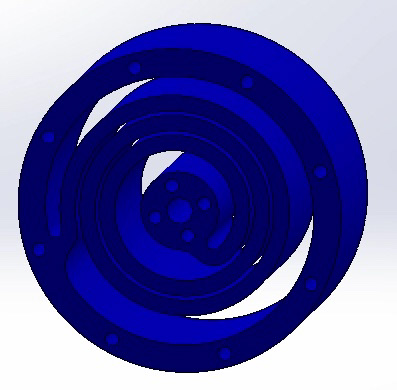

In order to validate and test these models we utilized Solidworks FEA. The below screen shots are from the final testing of the spiral planar springs. The calculations below drove our final design parameters of the torsional spring.

Spring parameterized calculations

Solidworks FEA simulation without yielding

Spring linearity validation

We also needed to ensure that the spring maintained infinite life so the below captures are of the fatigue simulation results.

After simulation completion, we wrote up a client report on our findings and potential approaches for manufacturing the final design.