Goal:

Design a MDF CNC fabricated flat packable acoustic guitar side bender. Bender utilizes hot swappable compression shoes and side profiles for establishing bend locations. The system also must have an integrated silicone heater controller for accurate wood steaming.

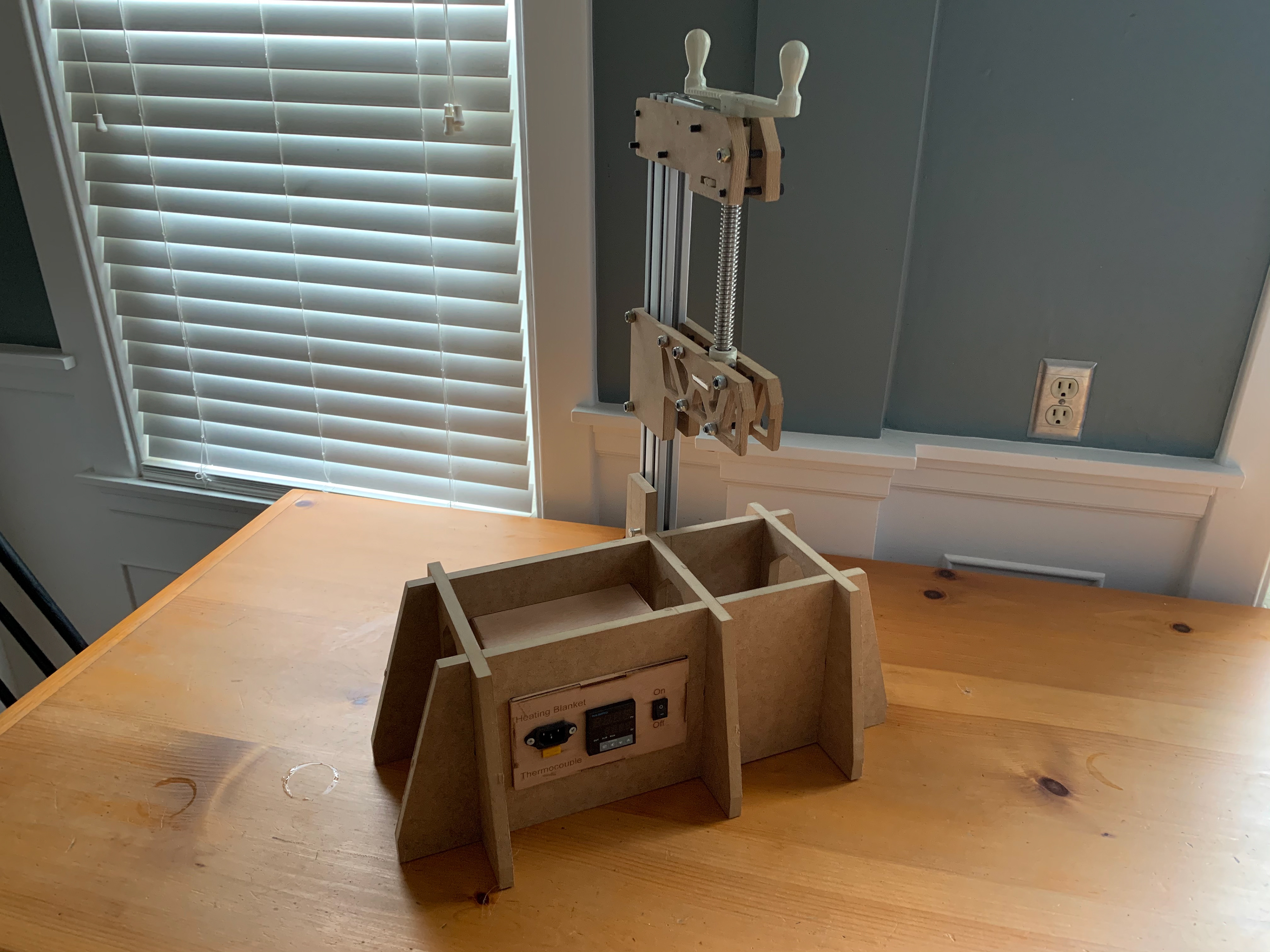

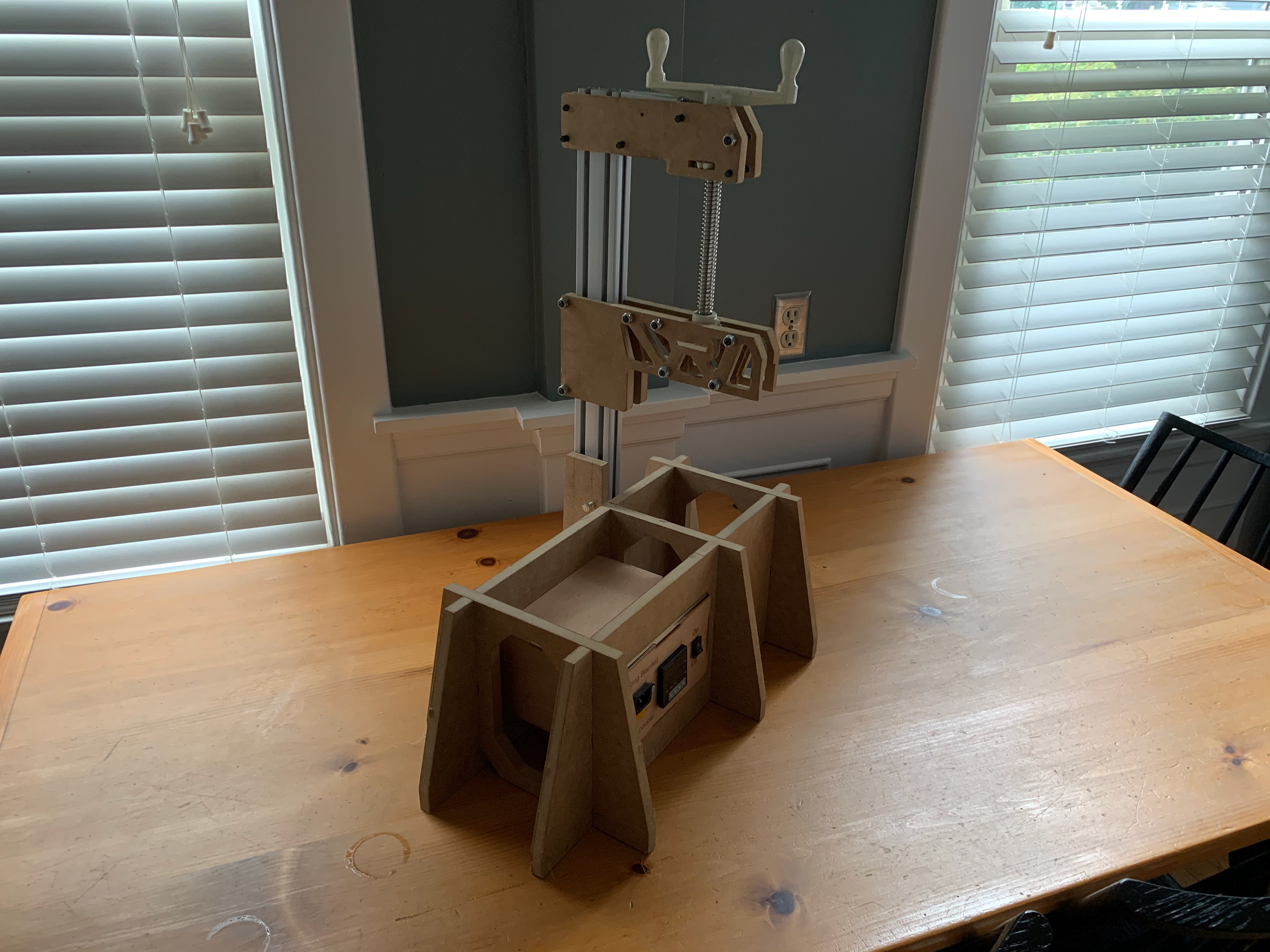

Final Product:

Approach:

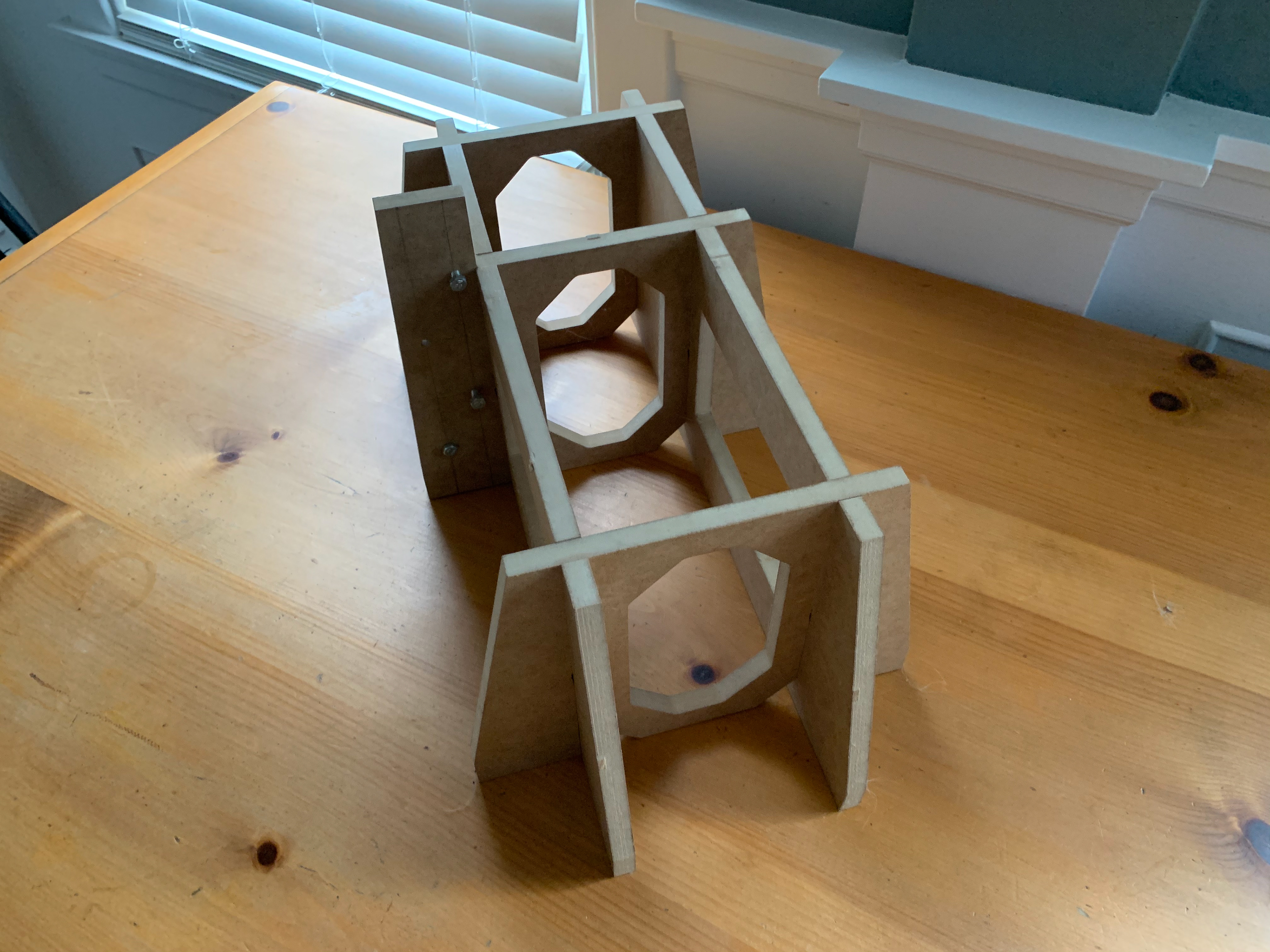

Base of the bender utilizes CNC milled cross joints to affix the MDF sheet sections. End mill radius compensation was necessary when determining the toolpathing for these sections. Due to the lack of small radius cutters I modeled two circular "ears" on each interior vertex of the receiving groove. By connecting a tangent path between these ears and the edge of the groove it is possible to minimize high tooth engagement in the milling operation.

Sketch of 0.25 in endmill toolpath in the base of the bender

Below are the final milled components for the base of the bender. The whole assembly is composed of friction fits. Once the cross pieces are installed the bender is pinned together.

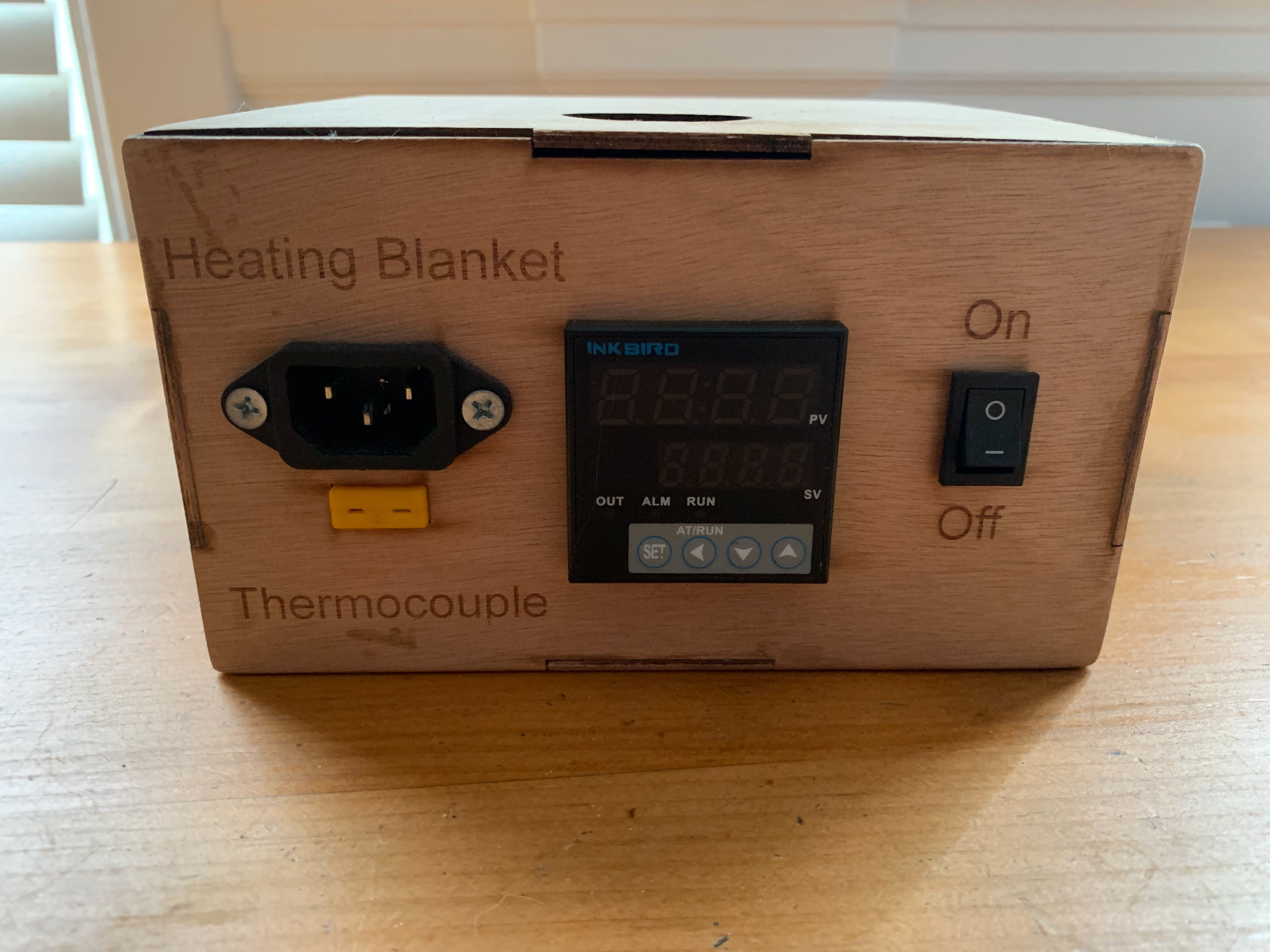

The next focus of the system was a temperature control unit to maintain desired wood temperature during bending. The brains of this unit is the Inkbird PID Temperature Controller with regulated power output for a heating blanket. A thermocouple is used for feedback of the current temperature of the wood while heating.

The unit is contained in a laser cut wooden box and photos of the completed unit can be seen below.

Below is a photo of the temperature controller installed into the base of the side bender.

The last component of the side bender is shoe clamp that utilizes a Shop Fox clamp and 40x20mm aluminum extrusion to apply pressure at the belly of the side profiles. Below are pictures of the final design.

Top of belly press clamp

Sliding arm of the belly press clamp

Complete belly press clamp assembly

This system has yet been tested by bending a set of acoustic guitar sides. As I finish up my college education, I plan to return and build my first acoustic guitar using this system.